After NADRA GROUP acquired a controlling stake in JSC Kyiv Plant Geofizprylad, the largest enterprise for producing geophysical tools for oil-and-gas well-logging operations in the former USSR, there was a need to establish a company to provide well services. This new company would be responsible for testing tools and the entire complex of equipment produced by the plant, with a particular focus on testing new developments. In 2000, NADRA Services LLC was established to meet this need and operate in the well-logging services market. Over time, NADRA Services LLC has acquired equipment from the best foreign manufacturers to provide world-class high-tech well-logging services to both Ukrainian and foreign production companies operating in Ukraine.

The company has conducted geophysical research in prospecting, exploratory, and development wells located in the Dnipro-Donets basin, the northern outskirts of the Donbas, and regions of Western Ukraine. NADRA Services LLC has successfully solved almost all tasks set by customers, including those in harsh geological environments. This includes deep wells with depths up to 6500 meters and operating temperatures of up to 200°C and pressures of up to 100 MPa.

The primary customer of the company's work works was the state enterprise UkrGasVydobuvannya. About 78% of the company's income was generated from work performed for UkrGasVydobuvannya.

The company also completed significant volumes of work for leading private companies such as PJSC Naftogazvydobuvannya, KUB-GAZ LLC, Energy Service Company, ESCO PIVNICH, and others.

Well-logging works were carried out by modern equipment, highly qualified and experienced specialists. As a result, commercial flow rates of hydrocarbons were obtained from many prospecting and exploratory wells, including those in the Aksyutivska, Korobochkinska North, Vasyshchivska, Khmarivska, Denisivske, and Semirenkivske fields, due to testing of selected objects recommended by our specialists. NADRA Services LLC even conducted downhole logging of the deepest well ever drilled on the Semirenkivske field, which had a total depth of 6,740 meters, and where a commercial flow rate was obtained.

NADRA Services LLC conducted a significant volume of work related to monitoring the development of oil and gas deposits, geophysical studies for monitoring the technical condition of wells, and geophysical studies during the operation of underground gas storage facilities of JSC Ukrtransgaz (such as Kegichivske, Krasnopopivske, Uherske, and others). In order to investigate the technical condition of wells, the company utilized the most modern equipment from the Sondex company in England. This included radial cementometry tools (RBT), 40-arm microprofilimeters (MIT), and electromagnetic defectoscopy tools (MTT). These tools provided the most reliable assessment of the condition of well casings and the quality of their cementation.

The enterprise successfully conducted technological, geophysical, and geological research using a mud logging unit. The crew operating the mud logging unit has been repeatedly recognized by customers as a highly professional team equipped with modern tools, allowing them to solve even the most complex technological and geological tasks. In the current year, the mud logging units were inspected, and the high quality of preparation for work execution was confirmed.

Surveys performed in an open hole:

- lateral logging;

- lateral logging and two-probe lateral logging;

- standard logging from SP;

- induction logging;

- micro-logging, micro-side logging with a caliper;

- radioactive two-probe neutron logging with gamma logging;

- neutron logging for slow and fast neutrons;

- density gamma-gamma logging;

- sonic logging with full full-waveform recording;

- caliper logging, doble axis caliper logging;

- directional logging;

- highly sensitive thermometry;

- TDT (pulsed neutron-neutron logging);

- geological and technological downhole surveying and gas logging.

Surveys performed in cased wells:

- sonic logging for cementing control;

- determination of annulus cement top;

- radioactive logging upon fast and slow neutrons with gamma logging;

- TDT (pulsed neutron-neutron logging);

- high-sensitivity thermometry;

- downhole surveying during development control with complex tools with simultaneous measurements by manometer, thermometer, gamma-ray meter, collar locator, hygrometer, thermoconductive flow meter, resistivity meter, noise meter (complex devices K-9, KSAT-7, PLT-9);

- multi-arm microcaliper (MIT);

- magnetic pulse defectoscopy (MTT);

- radial sonic cementometry (RBT).

Tasks solved while well-logging: Geological

- lithological subdivision of the record;

- detection of reservoir rocks;

- saturometry of the rocks;

- assessment of poroperm properties of the rocks;

- recognition of reference horizons.

Tasks solved while logging: Technological

- pre-drilling detection and control of oil and gas shows and mud losses during drilling;

- optimization of the well deepening process;

- selection and maintenance of a rational drilling regime with control of drilling bit wear;

- control of hydrodynamic pressure in the well;

- control of formation and pore pressures, forecasting of abnormal high and lower pressure zones;

- monitoring of drilling and prevention of emergency situations in real time.

Tasks solved while logging: Geochemical

- chromatographic analysis of the gas-air mixture (% abs) by component-wise registration;

- preliminary qualitative determination of the composition of the pore fluid;

- concentration of hydrocarbon gases (C1-C6), (6 components, % abs and % relative);

- total concentration of hydrocarbon gases (C1-C6, % abs);

- gas-mud mix release depth, m;

- bottomhole depth.

As a result of carrying out the above works, all typical tasks were solved:

- control of the well boring with determination of the coordinates of the bottomhole;

- stratigraphic and lithological subdivision of the well section;

- recognition of reservoir rocks;

- quantitative determination of poroperm properties of the reservoir rocks;

- determination of quantitative and qualitative parameters of reservoir saturation;

- quality control of casing cementing;

- detection of leakage places and behind-the-casing flows;

- control and analysis of field development processes

- secondary perforation of reservoir intervals;

- integrity monitoring of the casing.

Processing of measurement data was performed on the basis of NADRA Services in the system of automatic interpretation databases OPIUM, GEOPOSHUK, GEO.SKAPE and other special programs.

Geophysical, geo-technological and geochemical research in wells drilled for oil and gas

Electrical research methods:

Standard logging, side-wall resistivity logging (BKZ), lateral logging (BK), spontaneous polarization potentials (PS), profilemetry, resistivitymetry. The following types of equipment were used: EK-1, EK-AGAT, EK-NS, EK2-NN-150/150 (BKZ+2BK+PS + IR+KV).

Induction electromagnetic logging (IR). It was carried out with the following types of equipment: AIK-5M, IK1-NN-150/150 (AIK5).

Micromethods (MK) and lateral micrologging (BMK). They were carried out with the following types of equipment: MK-UC, MK-G, MK-NS.

Radioactive research methods:

Radioactive logging: gamma-ray logging (GC), neutron-neutron logging by slow neutrons (NNKt). The following types of equipment were used: SRK, SRK-NS, KURA-2M.

Gamma-gamma density logging (GGK-G). It was carried out with the following equipment: SHP2-AGAT.

Sonic research methods:

Sonic logging (AK), sonic cementometry (AKC). It was carried out with the following types of equipment: AKV-1, AK-AGAT.

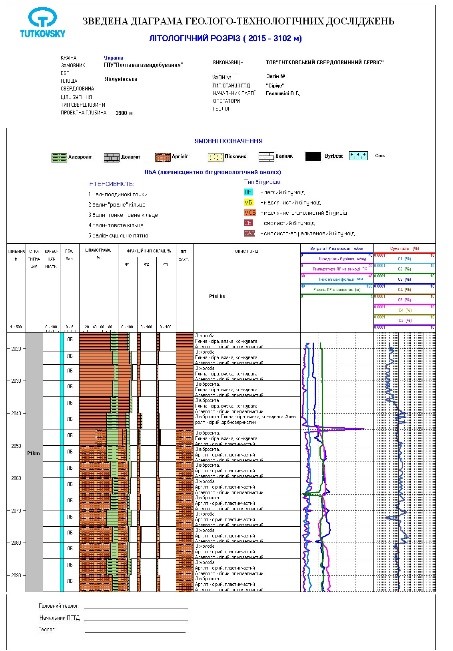

Upon the results of the completed complex of well-logging surveys, the Customer would receive the following materials for the well:

- a summary diagram of the well-logging research methods set with the main parameters as follows:

- lithological characteristics of the target beds;

- saturation character of the target beds;

- poroperm properties of formations: porosity ratio, oil and gas saturation ratio, net thickness of formations, formation resistance value, resistance value of the invaded formation;

- stratigraphic formation tops;

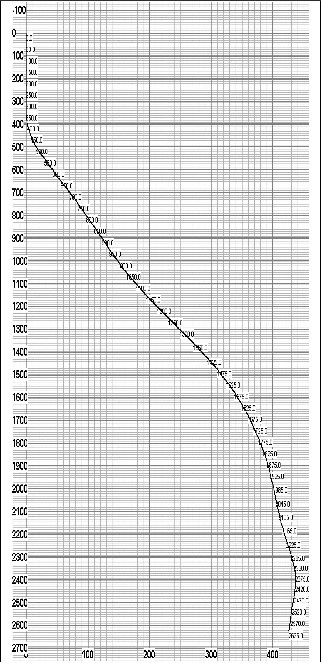

- directional log data with vertical and absolute depth scales.

- a summary diagram of standard and radioactive logging with the main parameters as follows:

- lithological characteristics of the target beds;

- saturation character of the target beds;

- poroperm properties of formations: porosity ratio, oil and gas saturation ratio, net thickness of formations, formation resistance value, resistance value of the invaded formation;

- stratigraphic formation tops;

- directional log data with vertical and absolute depth scales.

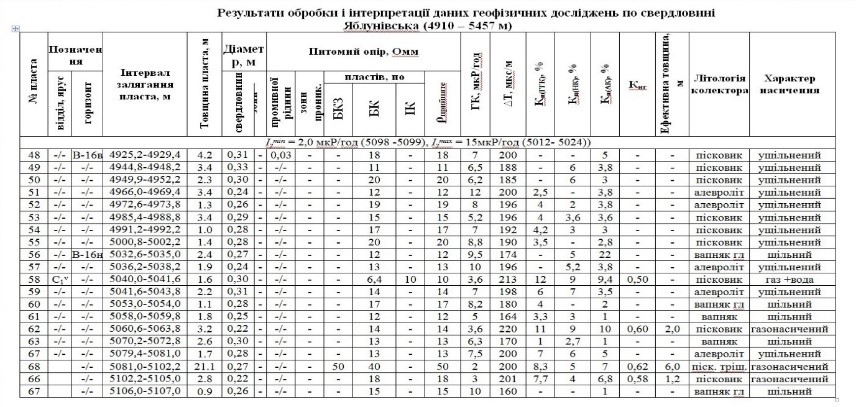

- conclusions based on the results of geophysical downhole surveying with a detailed description and tables with calculated parameters based on the performed studies, recommendations of experts regarding testing of prospective intervals;

- processing diagram of acoustic cement bond log data with a complete description of the quality of adhesion of cement stone to the casing;

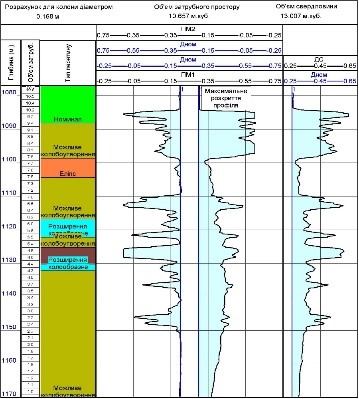

- the data processing diagram of caliper and profilemetry with calculations of the volume of the well and the volume of the annular space;

- thermal neutron die-away logging data processing diagram;

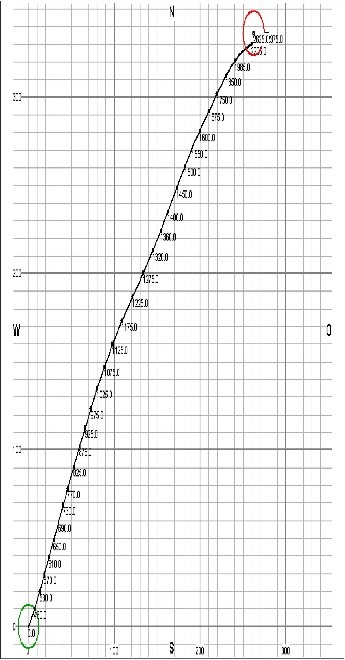

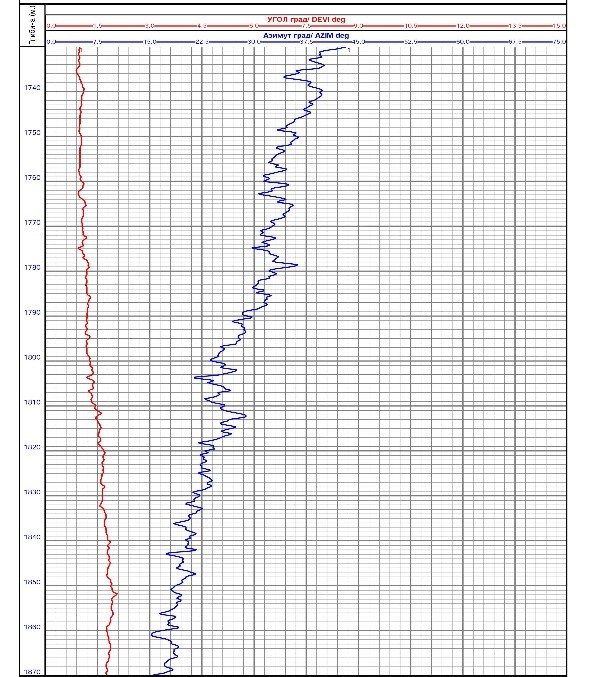

- directional log data processing, construction of the well plan and profile.

After completion and processing of the full range of the downhole surveys, the Customer would receive the following materials for the well:

- summary diagram of geological studies, summary diagram of geochemical and technological studies with the main parameters as follows:

- lithological subdivision along the wellbore;

- justification of the stratigraphic subdivision of the drilled section;

- character of saturation of selected beds by bitumen-luminescence analysis;

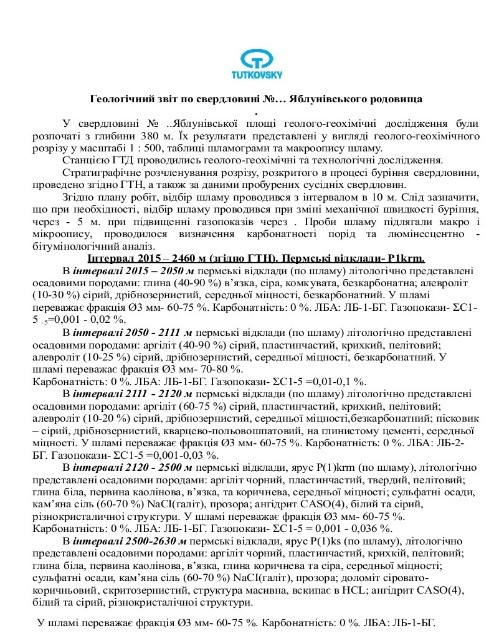

- geological report on the well;

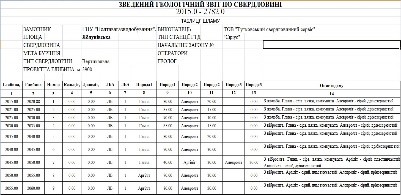

- table of slurry and core;

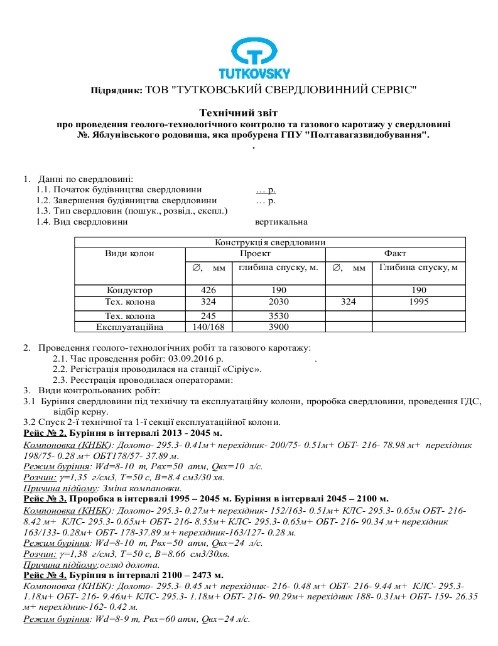

- technological report on the well design;

- explanatory note and table of recognized beds;

- diagrams of running casing.

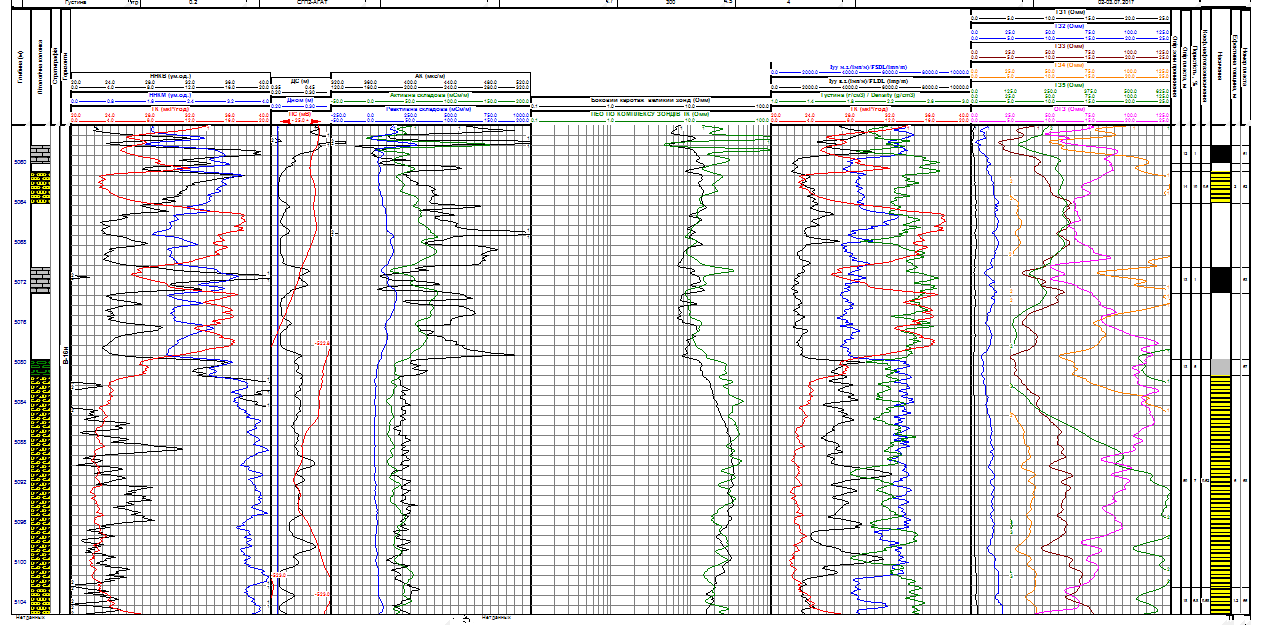

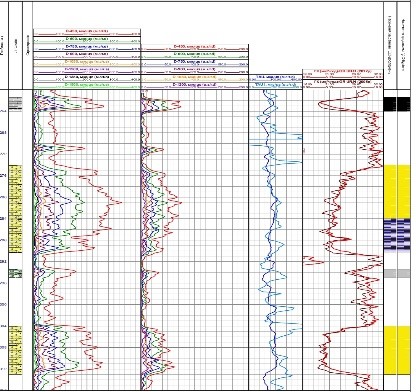

An example of a summary diagram of the well-logging research methods set

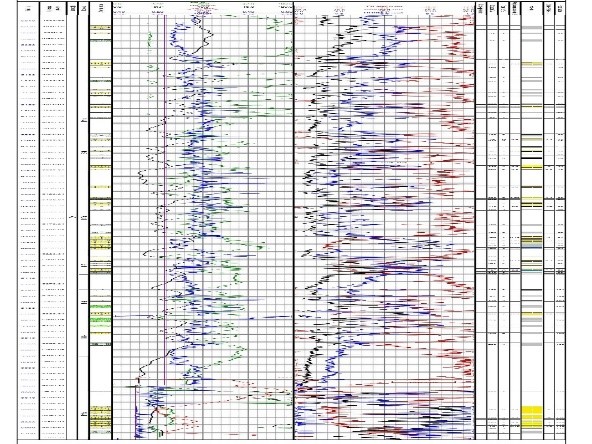

An example of a processing summary of standard and gamma-ray logs

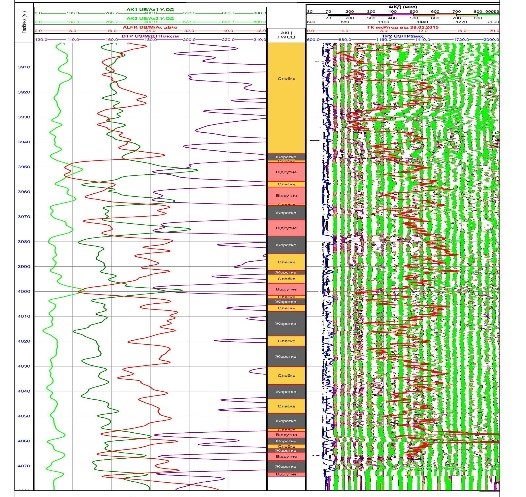

An example of a sonic cement bond log processing log

Other types of research:

Thermometry: Performed by TR-7 device, as well as in combination with other methods by PLT-9, KSAT-7 and K-9 devices.

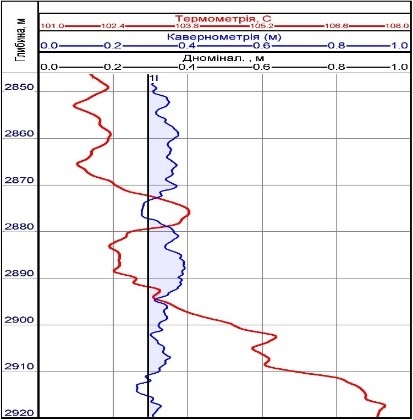

An example of a thermometry method processing log

Profilemetry: Performed by SKPD-3 device, as a separate method and in combination with EC series assemblies (EK-AGAT, EC-NS, etc.).

An example of the processing log of the caliper-profilemetry method

Direction logging: Performed by two types of equipment:

- KIT-A, KIT, of magnetometric continuous action type IMMN76-180/120.

- a continuous module of inclinometry along with a formation dipmeter.

An example of processing the directional logging: building of the plan and profile of the well, a diagram of continuous recording of the zenith angle and azimuth

Research by the method of pulsed neutron-neutron logging

Monitoring of current oil and gas saturation, justification of "product-water" contacts was carried out using the method of pulsed neutron-neutron logging (TDT). TDT were carried out applying the following type of equipment: AINK-43.

An example of a processing log of the TDT method

An example of the conclusions made by downhole survey data processing

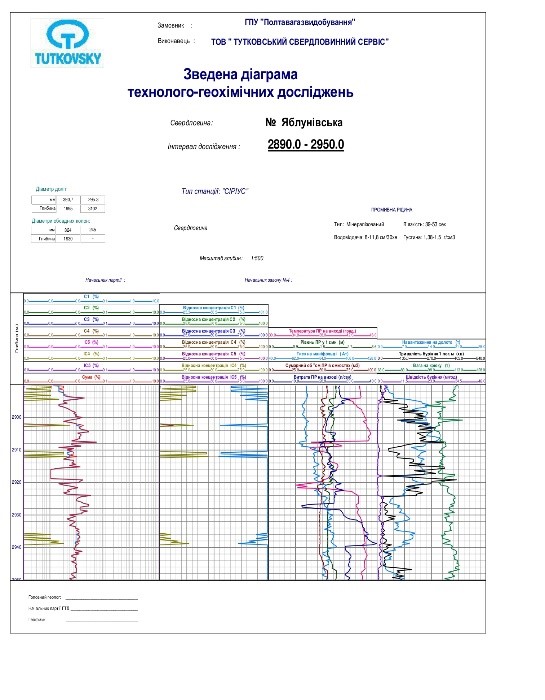

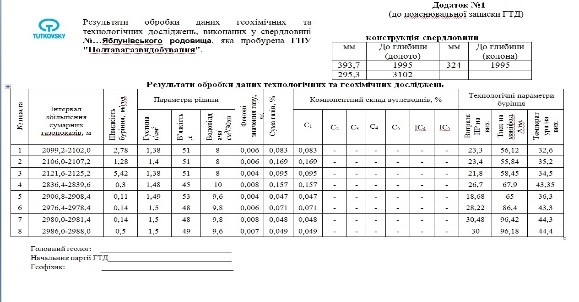

An example of a diagram of technological and geochemical research

An example of a lithological chart

An example of a slurry table

An example of a geological report

An example of a technological report

Example of a layer table

An example of an explanatory note